BattleJacket® Protective Coating Systems

Revolutionized self-sealing/self-healing spray-on protective technology for fuel tanks and tankers.

High Caliber Safety and Security

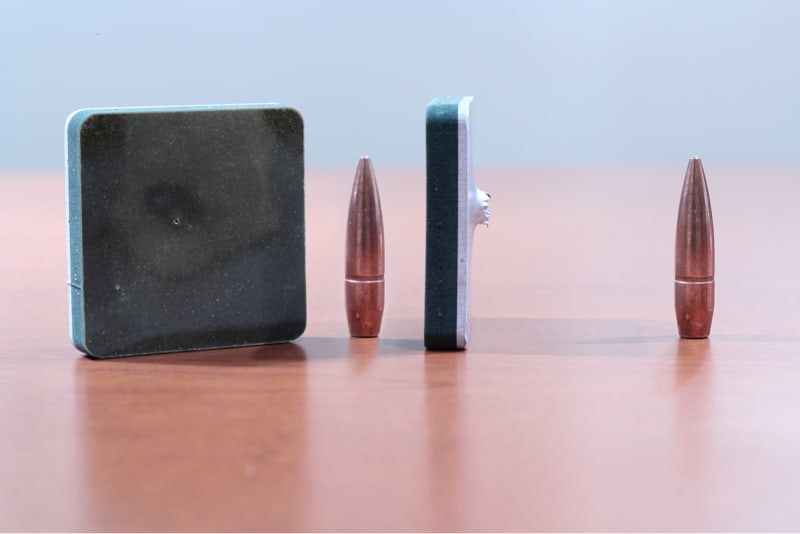

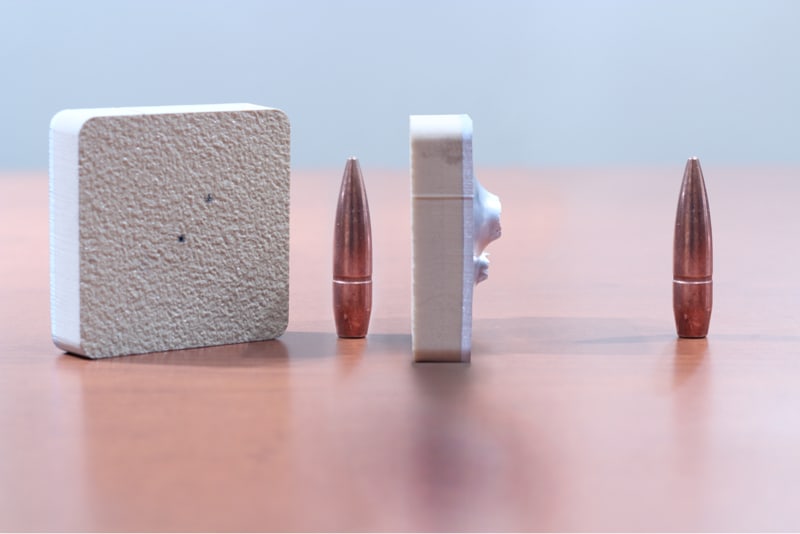

Battle-proven for nearly two decades throughout the U.S. military, BattleJacket® is HIT’s revolutionary self-sealing, self-healing fire protective urethane polymer coating used to protect vehicles, fuel cells, holding tanks, pipelines, railcars, and countless other assets. The BattleJacket® coating acts as an instant sealant when the coated surface is pierced by a bullet or projectile, mitigating fuel loss and potential subsequent explosion. Additionally, BattleJacket® protects treated surfaces from UV, weather, corrosion, fire and chemical spills. BattleJacket’s® patented system has multiple formulas, tailorable to meet your specific requirements.

Product Features

- Unique spray-on self-sealing / self-healing polymer, prevents fuel loss

- Can be applied to metals and plastic

- Adds protection from corrosion and abrasion

- Increases structural integrity

- Mitigates vibration and acoustics

- Sustains high pressures to 150 psi

- “Smart” embedded sensor capability

- Fire suppression integration

- Title 40 section 112 (Oil Pollution Prevention) compliant

Various BattleJacket® Coatings Include:

- Classic: -25°F TO 300°F temperature range.

- Extreme: -45°F TO 300°F temperature range.

- Aero: -60°F TO 300°F temperature range.

- BattleJacket® AQB (Aqua-Beads) Protective water tank coating validated against 50 caliber ballistic hits.